How Hydrogen and Depleted Uranium Can Solve the Wind Energy Integration Challenges

Hydrogen Depleted Uranium Storage coupled with Wind Energy Systems

Hydrogen is one of a handful of new low-carbon solutions that will play a critical role in the UK’s net-zero transition by 2050. Currently, natural gas is used to produce industrial hydrogen due to its low-cost nature but it results in large amounts of carbon emissions.

As an alternate solution to this problem, hydrogen can be produced via water electrolysis using clean energy sources such as wind, solar, and nuclear known as ‘green hydrogen’. No carbon emissions are released into the environment during the production of hydrogen using renewable energy sources and have minimal environmental impact. Furthermore, green hydrogen can offer the ability to store excess renewable energy from solar and wind which would otherwise go to waste at times of low-demand-surplus-energy scenarios. Power system operators currently implement a practice wherein they ask renewable energy generators to curtail their generation at times of excess supply compared to the demand. This approach is crucial particularly when there is inadequate storage capacity to manage the surplus energy. The battery energy storage systems face limitations, especially when addressing the storage requirements for extended periods and seasonal variation. Instead of wasting this surplus generation by curtailing the power generators, it could be converted into hydrogen and stored for longer durations. HyDUS emerges as a promising answer to such challenges at hand and helps prevent energy wastage. The innovative use of depleted uranium (DU) for the efficient and remarkable storage of hydrogen opens up new horizons for sustainable energy solutions. Providing a potential solution to address seasonal variations, particularly for scenarios of surplus power generation or when the power system requires additional energy.

Currently, hydrogen production from renewables accounts for less than 1% of the annual hydrogen production due to higher costs associated with it. Moreover, the efficiency of the conversion of hydrogen using electrolysis is comparably less. However, these challenges can be tackled by supporting innovation and stimulating investments to advance technology and driving their faster adoption. On this note, the UK government has set out the ‘UK Hydrogen strategy’ to capture the growing benefits of hydrogen ecosystems, such as the setting up of a 5 GW of low-carbon hydrogen production capacity by 2030. Under this strategy, hydrogen production will grow from small-scale (early 2020s) to several large-scale electrolytic productions (late 2020s) to achieve wide use of hydrogen in industry, power, and transport.

While any clean energy source can produce green hydrogen, governments, and energy utility companies across the world show interest in offshore wind power plants that are coupled with hydrogen storage. In particular, the attractiveness of offshore wind plants is that instead of electrons they can allow hydrogen to be produced offshore and sent back to shore thus alleviating congested power grids. Furthermore, there are some significant challenges to the integration of massive amounts of offshore wind power that can be solved by coupling with the green hydrogen sector. A couple are listed below:

- high levels of intermittency/variability associated with wind power generation places supply-demand grid balance at risk

- the requirement of grid reinforcements in the offshore power plants to integrate hard-to-abate sectors such as heavy-duty transport sectors (marine vessels/aviation etc.) and, the steel industry, which demand more energy-dense carriers.

Compared to electricity, hydrogen can be stored for a longer duration and in larger quantities, which in turn supports grid balancing, avoiding grid reinforcements, and can be used as green fuel for many other applications. Today, the declining costs of offshore wind power combined with the ambitious goals set by various countries (especially in Europe) to set up more offshore wind power plants makes this energy source a promising choice for large-scale green hydrogen production.

The UK offers favorable conditions to harness offshore wind power, generating over 70% of its power emissions-free, with a significant contribution from offshore wind power plants—a proportion higher than that of many other countries. Additionally, the ambitious target of 40 GW of offshore wind capacity by 2030 will be the primary route to the decarbonisation of aspects of the energy systems and support to electrolytic production of hydrogen.

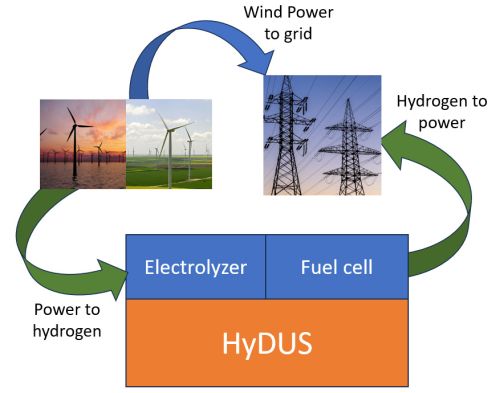

Once the bulk production of hydrogen is established by utilising both the onshore and offshore wind resources, HyDUS can play a significant role in storing the hydrogen to be later used for heat, power, and transport. The coupling of HyDUS with wind power plants could help in tackling one of the key barriers to flexible power generation. The integration of hydrogen into the power grids can bring the power-gas-power to balance the grid and offer grid flexibility. The electrolytic hydrogen production draws ‘excess’ wind power at times of low demands, that would otherwise be curtailed or constrained.

In simpler words, excess energy from wind farms can be harnessed to produce hydrogen, which is then stored in depleted uranium through HyDUS technology for future use. Later, this stored hydrogen can be transformed back into electricity using fuel cells during periods of high demand or can be utilised for various hydrogen applications. By leveraging the unique properties of depleted uranium, HyDUS not only offers cutting-edge technology to store hydrogen but also contributes significantly to the advancement of environmentally friendly and sustainable energy systems.

Unlocking a wide range of routes for using hydrogen opens up diverse avenues to market hydrogen and renewable power. Ultimately, the establishment of this robust UK-hydrogen ecosystem is poised to propel the nation toward a net-zero energy future, offering substantial economic opportunities across the UK once it is fully operational.

Research Associate, University of Bristol School of Electrical, Electronic and Mechanical Engineering